Navy Ship Maintenance: Evaluating Pilot Program Outcomes Could Inform Decisions to Address Persistent Schedule Challenges

Fast Facts

The Navy changed how it contracts for ship repair in 2015, in an effort to get this work done on time and at lower cost.

We found that the Navy has lowered costs from initial estimates for ship repair. But that work continues to run over schedule—due, in part, to the extra time it often takes to coordinate funding for additional repairs that may have been expected but could not be quantified when the contract began. The Navy is testing a potential solution via a pilot program, but doesn’t have plans to assess its impact.

We recommended that the Navy establish plans for evaluating lessons learned from this pilot program.

The USS Fitzgerald, an Arleigh Burke-class guided missile destroyer

Military vessel

Highlights

What GAO Found

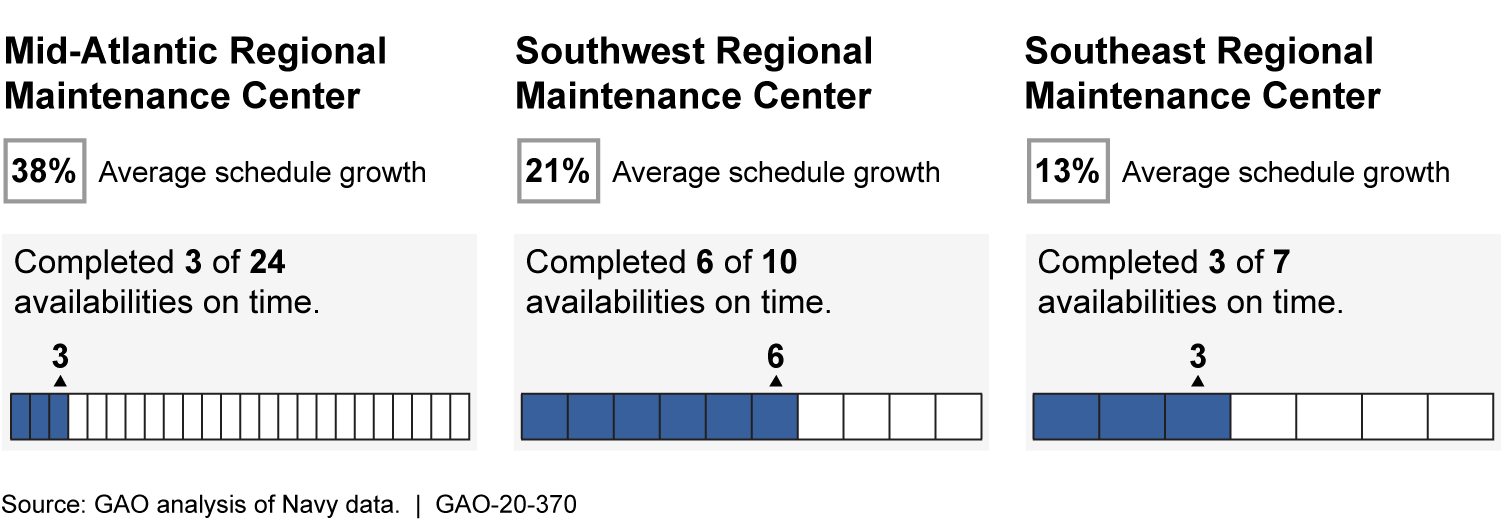

Since shifting to the Multiple Award Contract-Multi Order (MAC-MO) contracting approach for ship maintenance work in 2015, the Navy has increased competition opportunities, gained flexibility to ensure quality of work, and limited cost growth, but schedule delays persist. During this period, 21 of 41 ship maintenance periods, called availabilities, for major repair work cost less than initially estimated, and average cost growth across the 41 availabilities was 5 percent. Schedule outcomes were less positive and Navy regional maintenance centers varied in their performance (see figure).

Schedule Performance across Navy Regional Maintenance Centers

To mitigate these delays, the Navy has identified and taken actions to implement lessons learned, including negotiating and funding undefined but expected increases in work at the time of contract award. However, these actions have not resolved the delays that result from the approval process the Navy often must use to obtain funds to complete this maintenance work. Namely, if an availability extends into a new fiscal year and needs more than $4 million in additional prior-year funding, both Navy and Defense Department approvals are required. GAO found this approval process took between 26 and 189 days based on Defense Department data. In December 2019, Congress established a pilot program that would potentially allow the Navy to avoid this process. Leading practices GAO identified for pilot programs call for development of an analysis plan to track implementation and performance and for evaluating final results. As the Navy moves into implementation of its pilot program, developing an analysis plan would provide it with a means to identify opportunities to evaluate schedule outcomes of pilot program availabilities, as compared to non-pilot program availabilities, and document a process for evaluating lessons learned from the pilot program. Such evaluations would provide information to determine if the pilot approach should expand to help address persistent schedule challenges.

Ship repair contractors now operating in the MAC-MO environment told GAO that two key considerations drive their decisions on workforce and facilities investments: visibility regarding planned workloads within a given port and their assessment of the share of that work they are most likely to win. In recognition of these considerations, Navy officials have begun taking steps to increase predictability of workloads at each port. These officials anticipate that these steps, coupled with increasing workloads at the ports, will help increase contractors' confidence in their ability to forecast their share of future work.

Why GAO Did This Study

The Navy relies on its fleet of over 150 surface ships to be ready to operate when needed for the defense of the United States. The Navy spends billions annually in maintaining this fleet. In 2015, the Navy changed how it contracts for such maintenance work, aiming to better control costs and improve quality. The new approach, called MAC-MO, generally uses firm-fixed-price contract delivery orders for individual ship availabilities competed among pre-qualified contractors at Navy regional maintenance centers.

House Report 115-676 included a provision for GAO to review the Navy's implementation of the MAC-MO strategy. This report (1) examines outcomes under the strategy; (2) evaluates actions the Navy has taken related to recent lessons learned; and (3) describes contractors' considerations when planning for hiring and facilities. GAO analyzed data on ship repair under MAC-MO; reviewed six case studies involving different availability types, classes of ships, maintenance centers, and contractors; and interviewed Navy officials and contractors.

Recommendations

GAO recommends that the Navy establish an analysis plan for the evaluation of the pilot program. The Navy concurred with GAO's recommendation.

Recommendations for Executive Action

| Agency Affected | Recommendation | Status |

|---|---|---|

| Department of the Navy | The Secretary of the Navy should establish an analysis plan for the evaluation of OPN-funded pilot program availabilities, based on the leading practices for pilot programs. This analysis plan should identify opportunities to evaluate schedule outcomes of pilot program availabilities as compared to non-pilot program availabilities and document a process for evaluating lessons learned from the pilot program (Recommendation 1). |

The Department of the Navy concurred with our recommendation, stating that it would establish an analysis plan for evaluating Other Procurement, Navy-funded pilot program availabilities. Since then, the Director, Maintenance & Modernization, within the Office of the Deputy Assistant Secretary of the Navy for Ship Programs, has submitted a series of reports to Congress outlining the Navy's performance evaluations on the private contracted ship maintenance pilot program. These reports have contained some elements of our recommended analysis plan in that they describe opportunities to evaluate schedule outcomes of pilot availabilities as compared to non-pilot availabilities. However, these reports have not yet identified a process for evaluating lessons learned from the pilot and facilitating related communications with stakeholders. Correspondent with these reports, the Navy has also issued reports to Congress regarding the execution of funds used for pilot program implementation. These reports have identified some elements of a methodology that could be used to evaluate pilot program outcomes, but have not yet described processes for evaluating lessons learned or facilitating related communications with stakeholders. The Director, Maintenance & Modernization stated in July 2023 that the Navy is continuing its work to fully address the recommendation, including consideration of a process for collecting and communicating lessons learned. However, the Director stated that the Navy does not have an expected timeframe for completion of these efforts. We are currently awaiting information regarding this process and will continue to monitor progress. We will also continue to review the Navy's future reports for the pilot program and the ship depot maintenance budget to assess the Navy's responsiveness to our recommendation.

|