F-35 Joint Strike Fighter: Program Continues to Encounter Production Issues and Modernization Delays

Fast Facts

After nearly 20 years, the F-35 program moved into full-rate production after conducting its final simulated tests. At this milestone, DOD determined that the F-35 demonstrated an acceptable level of performance and reliability and could be manufactured faster.

However, contractors continue to deliver engines and aircraft late—a trend that has worsened in the last few years. The program also faces delays in updating the aircraft's software and has been slow to modernize the engine and other aircraft components.

We previously made recommendations to help the F-35 program address these challenges, but DOD has only implemented some of them.

Highlights

What GAO Found

The F-35 program achieved full-rate production in March 2024. Full-rate production is the point when a program has demonstrated an acceptable level of performance and reliability. Further, the F-35 program completed development of its testing simulator and conducted its final simulated tests.

Even with this progress, the F-35's contractors continue to deliver the engines and aircraft late—a trend that worsened in the last few years. According to program officials, late deliveries were partially caused by manufacturing issues and parts shortages. The program and contractors are mitigating these issues.

Percentage of Engines and Aircraft that Contractors Delivered Late in Calendar Year 2023

|

Contractor |

Parts delivered |

Percentage delivered late |

|---|---|---|

|

Pratt & Whitney |

Engines |

100 |

|

Lockheed Martin |

Aircraft |

91 |

Source: GAO analysis of contractor data. | GAO-24-106909

Hardware and software delays—specifically those associated with Technology Refresh 3 (TR-3)—are another factor driving delays and hindering the program's progress in completing the Block 4 modernization. TR-3 is a $1.8-billion suite of hardware and software upgrades that are critical to the Block 4 modernization effort. TR-3 suppliers have faced setbacks including supply chain issues and software issues. The program and contractor are resolving these issues.

The program made some progress in its recent efforts to modernize the engine and other subsystems but has not awarded a development contract.

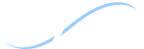

Diagram of Engine and Engine Core Components Included in F-35 Modernization Effort

The program also has not yet determined how to modernize the thermal management subsystems that provide cooling to the aircraft. These efforts continue to face risks due to undefined requirements, immature technologies, and varying cost estimates. GAO has made recommendations to address these risks, which the program has not yet fully implemented.

Why GAO Did This Study

After over 20 years, the F-35 Lightning II Joint Strike Fighter program—the Department of Defense's (DOD) most expensive weapon system program—completed its baseline development phase and moved into full-rate production. DOD is in its sixth year of a hardware and software modernization effort known as Block 4 and is considering other modernization efforts. DOD estimates that these development efforts—as well as the costs to maintain and operate the 2,470 planned aircraft through 2088—will exceed $2 trillion.

Congress included provisions in statute for GAO to review the F-35 program. This report assesses the program's: (1) progress and risks as it approached full-rate production; (2) progress in modernizing the aircraft's capabilities; and (3) progress in upgrading the engine and other subsystems.

GAO collected and analyzed cost, schedule, and production data; reviewed relevant program documentation; and interviewed DOD officials and contractor representatives.

Recommendations

GAO has reviewed the F-35 program annually since 2001 and made 54 recommendations for improvement. In May 2023, GAO made seven recommendations aimed at improving Block 4 cost reporting and the program's modernization efforts (GAO-23-106047). DOD has taken action to address some, but not all, of GAO's recommendations.