Science & Tech Spotlight: Advanced Plastic Recycling

Fast Facts

Plastic waste—overflowing landfills and polluting oceans—has grown tenfold in the U.S. from 1970-2018, as recycling rates have remained low.

Chemical recycling is an alternative or complementary technology to current mechanical recycling processes (like sorting and shredding). Chemical recycling technologies use heat, chemical reactions, or both, to recycle used plastic into new plastic, fuel, or other chemicals—creating a closed loop where plastics can be infinitely recycled to help reduce reliance on landfills.

But, adopting chemical recycling technologies faces hurdles, like high startup costs and few incentives for investing in innovation.

Highlights

Why This Matters

Plastic waste in the U.S. has grown tenfold from 1970 to 2018, while recycling rates have remained low. Mounting plastic waste in landfills and oceans can contaminate ecosystems and adversely affect human health and wildlife. Chemical recycling technologies have the potential to improve plastic recycling, but several challenges remain.

The Technology

What is it? Plastics are found in many everyday items—including food packaging, water bottles, bags, and appliances. They are largely made from fossil fuel-based chemicals combined with various additives—such as stabilizers or flame retardants—to achieve a desired result (e.g., strength, rigidity, color, heat resistance).

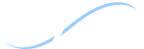

The majority of plastic waste in the U.S. ends up in landfills, with a relatively small portion incinerated and an even smaller portion recycled. The accumulating plastic waste in landfills generally does not biodegrade or break down.

Figure 1. Methods of plastic waste disposal in the U.S.

Plastic recycling technologies reprocess or remanufacture plastic waste for reuse. Currently, the dominant technology for plastic recycling is mechanical recycling, which uses physical processes—such as sorting, grinding, washing, separating, drying, and re-granulating—to recover plastics that can be substituted for virgin, or new, plastics. However, mechanical recycling technology is expensive, labor intensive, and generally results in lower quality plastics than virgin plastics. Consequently, industry is considering advanced recycling technologies— namely, chemical recycling—as an alternative or complement to mechanical recycling. Chemical recycling technologies use heat, chemical reactions, or both, to recycle used plastic into virgin-equivalent plastic, fuel, or other chemicals.

In addition, recent advances in sorting technology—one of the physical processes common to both chemical and mechanical recycling technologies—may also increase the efficiency of chemical recycling and lead to increased plastic recycling. For example, artificial intelligence technologies have the potential to increase automated sorting efficiency. Similarly, another advanced technology efficiently sorts materials by identifying their molecular vibrations.

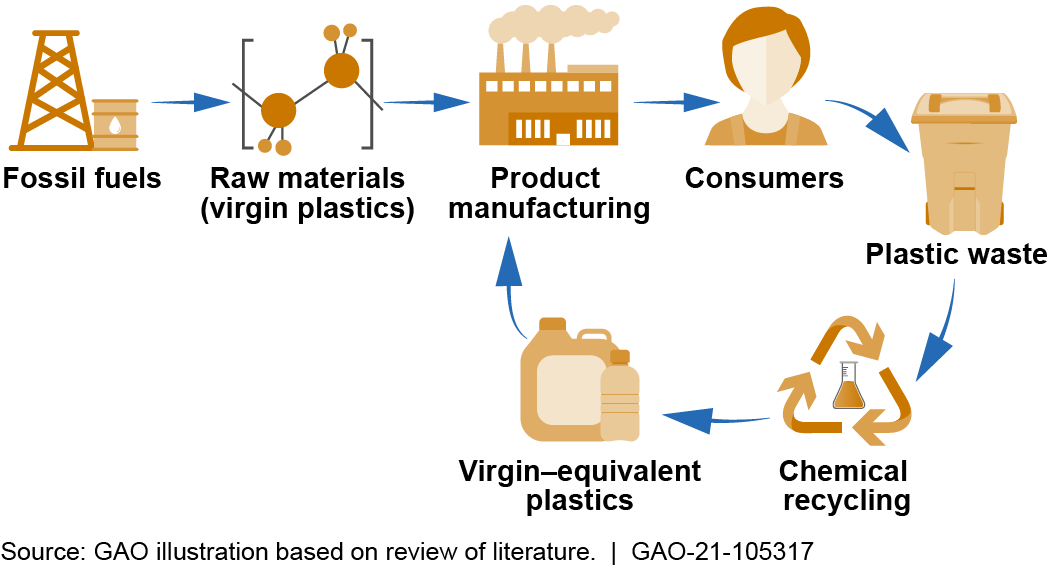

How does it work? Chemical recycling can promote a closed-loop system, known as a circular economy, wherein plastics are reused rather than discarded in landfills or incinerated. There are three general categories of chemical recycling technologies: conversion, decomposition, and purification.

Figure 2. Closed-loop chemical recycling

Conversion focuses on converting polymers—long-chain hydrocarbon molecules built from smaller repeating units called monomers—in mixed or sorted plastics into smaller molecules. This can occur through a variety of techniques, including pyrolysis and gasification.

- Pyrolysis, sometimes called "plastics to fuel," turns plastic waste into a synthetic crude oil that can be refined into diesel fuel, gasoline, heating oil, or waxes. This process involves heating the plastic waste to high temperatures (300-900°C) in the absence of oxygen. Different forms of pyrolysis use different temperatures, pressures, and processing times.

- Gasification also heats plastic waste to high temperatures (500- 1300°C) in a low-oxygen environment to convert plastic waste to synthesis gas, or "syngas." Syngas—a fuel mixture containing mainly hydrogen and carbon monoxide—can be combusted for electric power generation or converted into other fuels or chemicals, such as ethanol and methanol.

Decomposition breaks down polymers in sorted plastics into monomers to produce new plastics. This decomposition can be done with heat or chemicals. Chemical decomposition uses solvents to break the polymers into monomers. Some decomposition technologies use enzymes to break down polymers at temperatures as low as room temperature, resulting in less energy consumption.

Purification uses solvents to separate polymers from additives or contaminants. Unlike other types of chemical recycling, purification does not break or modify the polymer. Purification may be used with mixed or sorted plastics.

How mature is it? While technologies such as pyrolysis and gasification are mature, their use in plastic recycling is relatively new, due in part to the low cost of virgin plastic material and the challenges associated with recycling contaminated or complex plastic products. Conversion is currently the most mature of the chemical recycling technologies, with several companies using pyrolysis, and at least one company using gasification on a commercial scale. Several companies are also developing, or are in the initial phases of piloting, thermal and chemical decomposition. Purification is the least mature chemical recycling technology, although research into it is ongoing. Advanced sorting technologies vary in maturity, with molecular vibrations for material identification already in use, and artificial intelligence sorting still under development.

Opportunities

- Resource conservation. Chemical recycling can produce raw materials of virgin quality, thereby decreasing demand for fossil fuels and other natural resources.

- Reduced landfill use. A significant amount of plastic waste ends up in landfills. New technologies could reduce the need for landfills, which may reduce the release of harmful chemicals into the environment.

- New markets. Developing advanced recycling technologies could promote domestic business and employment. Chemical recycling creates a market for plastic waste and a new way to reuse some plastics.

Challenges

- Adoption hurdles. Companies looking to use chemical recycling may face several hurdles, including process and technology challenges, high startup and operating costs, underdeveloped domestic markets for recycled products, and limited incentives for recycling innovation and investment.

- Suitability. Chemical recycling may not be suitable for all types of plastic, particularly when polymer chains are irreversibly bonded together.

- Competition. Virgin plastics are typically cheaper to produce than recycled plastics, in part due to transportation costs and limited recycling infrastructure, making it hard for recycling processes to compete.

Policy Context & Questions

With the volume of plastic waste expected to grow over time, some key questions for policymaker consideration include:

- What steps could the federal government, states, and other stakeholders take to further incentivize chemical recycling rather than disposal? What are the potential benefits and challenges of these approaches?

- What steps could policymakers take to support a transition toward a circular economy, including innovation and investment in manufacturing and recycling capacity?

- What might policymakers do to promote advanced recycling technologies while also reducing the hazards associated with existing plastic production and recycling methods?

For more information, contact: Karen L. Howard at (202) 512-6888 or howardk@gao.gov.