Science & Tech Spotlight: Nuclear Microreactors

Fast Facts

Cyberattacks and natural disasters can pose risks to the electric grid across the country, potentially resulting in blackouts and other disruptions to daily life.

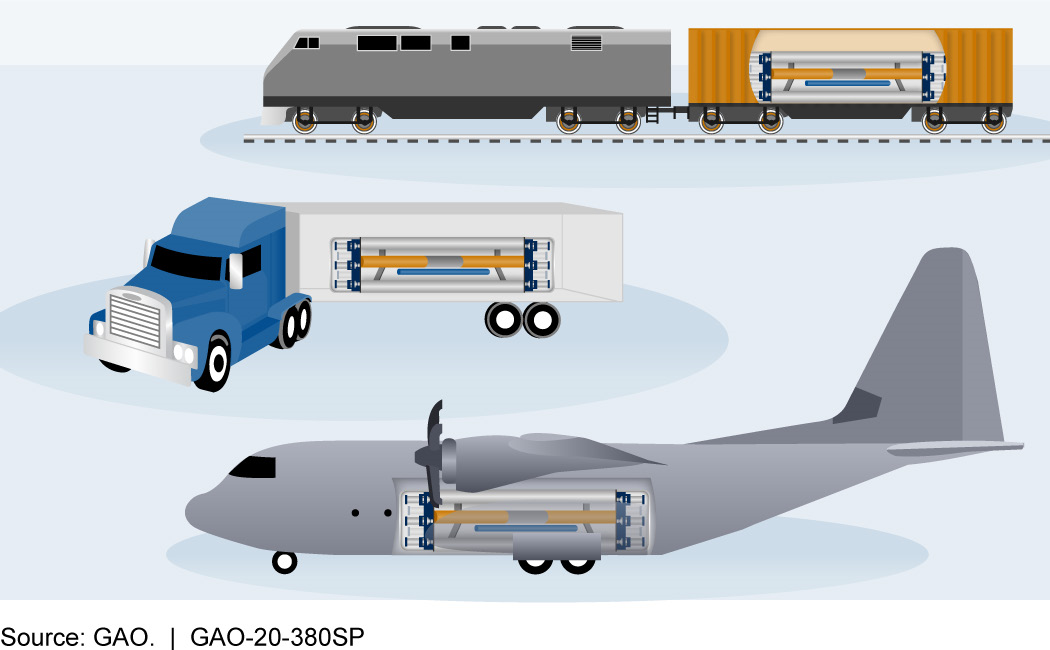

Nuclear microreactors are an emerging technology that could help affected areas get back up and running faster. Compact and mobile, fully-assembled microreactors could be transported by rail, truck, or plane to wherever they are needed.

Challenges to implementing this technology include:

availability of fuel and related nuclear proliferation issues

strategies for waste treatment and disposal

total time needed for development and regulatory reviews

Potential transportation for microreactors

Figure showing how microreactors would fit in a train, truck, or plane

Highlights

Why This Matters

The U.S. nuclear energy sector faces an uncertain future. Nuclear microreactors offer the potential of faster deployment compared to conventional large reactors, but they face challenges such as limited fuel availability and greater security risks. Given long design and certification cycles, examining microreactors now is key for future industry planning.

The Technology

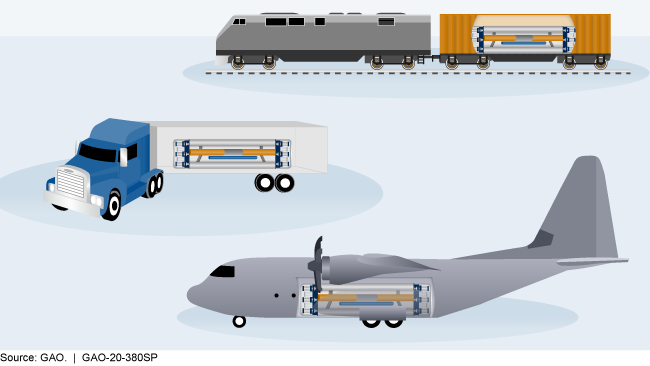

What is it? Nuclear microreactors are very small reactors usually generating less than 50 megawatts electric (MWe). They are seen as an alternative to conventional (often around 1,000 MWe) or small modular reactors (50-300 MWe). By comparison, microreactors can be produced more quickly, and within weeks, transported and deployed to locations such as isolated military bases or communities affected by natural disasters. They are designed to provide resilient, non-carbon emitting, and independent power in those environments.

Figure 1. Conventional nuclear reactors produce around 1,000 megawatts electric (MWe) and can power cities. Microreactors generally produce less than 50 MWe and could supply enough power for smaller communities in remote locations.

How does it work? Similar to conventional large reactors, microreactors use the heat from a nuclear reaction to boil water, creating steam. The steam spins a turbine generator that, in turn, produces electricity. Depending on the proposed design, microreactors would use either more mature conventional light water or less mature advanced reactor technologies. Many of the designs call for the use of fuel enriched up to 20% U-235 (high-assay, low-enriched uranium, or HALEU), which is currently unavailable in the commercial U.S. market, and may also present proliferation and safety risks. Other innovations, such as improved cooling, heat transfer, and different approaches to manage the reaction, are also needed to sustain a nuclear reaction in a much smaller package than that of conventional nuclear reactors. The smaller size makes a microreactor transportable by truck, train, or cargo plane.

Figure 2 Microreactors are designed to be transportable by rail, truck, or cargo plane.

How mature is it? Microreactors are currently in the earliest stages of development, with individual designs ranging in maturity. (Designs for small modular reactors that in some cases have been supported by the Department of Energy are at later stages of development.) Before a reactor can be deployed, many years of careful planning and close coordination between reactor designers and regulators are required.

How far along any given design is depends on the proposed technical approach. Designs using light water cooling are nearing maturity, as they are based on components that are proven to be effective in large conventional reactors. Designing large reactors can take over 10 years, including more than 3 years for Nuclear Regulatory Commission design certification and cost $1 billion to $2 billion (in 2015). By comparison, reactors using advanced concepts, such as liquid metal, molten salt, or high temperature gas, will require more design and certification work, which would lengthen the development time. Because of the time required to design, certify, and manufacture microreactors, examining this technology now is key for future planning by the industry.

Opportunities

- Faster, cheaper, and more efficient production. With the smaller reactor size, the entire reactor could be factory-assembled under controlled environmental conditions with quality control procedures. Complete assembly in the factory could increase the production rate of the reactor components, create cost efficiencies through greater economies of scale, and reduce the time needed for installation in the field. The turbines, generators, and other associated parts could also be manufactured in a factory as modular units and added on-site.

- Rapid deployment to natural disaster areas. Having another option for restoring power quickly following natural disasters would support faster restoration of critical services such as hospitals, communications, and the water supply to the local community.

- Greater resiliency. Being able to quickly transport and deploy alternate sources of power generation, in conjunction with microgrids, to isolated military bases, rural communities, and remote businesses may allow such communities to operate more independently, especially at difficult times such as during the rapid establishment of military operations or after a severe weather event has damaged power transmission lines.

- Safer operation. Some designs allow for the use of passive safety systems and operation without refueling for 10 years or more, which may reduce the likelihood of accidents.

Challenges

- Limited fuel availability. HALEU fuel is not currently available in the commercial market, though the Department of Energy plans to support research into the development of fuel and a demonstration of microreactor technology at its Idaho National Laboratory site. Some microreactor designs may require modification to use alternative fuels, may not be able to be certified until HALEU is available, or simply may not be viable.

- Greater security and proliferation risk. Microreactors using HALEU fuels may increase security and proliferation risks, especially if exported overseas to many locations, increasing opportunities for theft of nuclear fuel. With its higher enrichment levels, HALEU would require greater security than traditional fuel types at all facilities in the fuel cycle. Furthermore, using HALEU or higher enriched fuel in a microreactor makes it a more attractive target for theft or diversion into a weapons program because less work is needed to make it into weapons-grade uranium.

- Waste stream challenges. New or novel fuels could present challenges for waste treatment and disposal, similar to or greater than those faced by current commercial reactors. For example, some advanced reactor designs use unique fuels incorporating reprocessed nuclear material, which may require adjustments to waste handling as compared to large light water reactors.

- Regulatory challenges. Some designs may not be effectively addressed by current regulatory approaches and could require modifying or developing new regulations. For example, existing regulations for large reactors stipulate on-site staffing in control rooms. If a microreactor designer wants off-site staffing, they could request that regulators consider modifying the regulations. In addition, long design certification lead times could delay deployment.

Policy Context and Questions

With interest in microreactors growing within the defense and energy industries and key technologies not yet mature, some questions for consideration include:

- What is known about the level of demand or interest in microreactors to support such a market?

- What actions, if any, could the federal government take to regulate or improve operations of the microreactor supply chain?

- What investments or regulatory adjustments, if any, could the federal government make to accelerate the deployment of microreactor technology?

- What security, proliferation, and safety risks do microreactors pose due to increased portability and the potential use of higher enriched fuel? How can such risks be mitigated?

For more information, contact Karen Howard at (202) 512-6888 or HowardK@gao.gov.